Presentations to the Idaho Manufacturing Alliance and Western Wood Preservers Institute

March and June 2023

Debra Mervyn

About 10 years ago, one of my clients was having problems with a China supplier quality and delivery. During my tenure at CH2M Hill, I learned of Activity Based Cost Accounting (ABC), developed by a couple of Portland State University Professors in the 1990s. I conceived a notion of following the Value Stream and determining labor, direct and indirect costs and solutions, a version of ABC light.

Why?

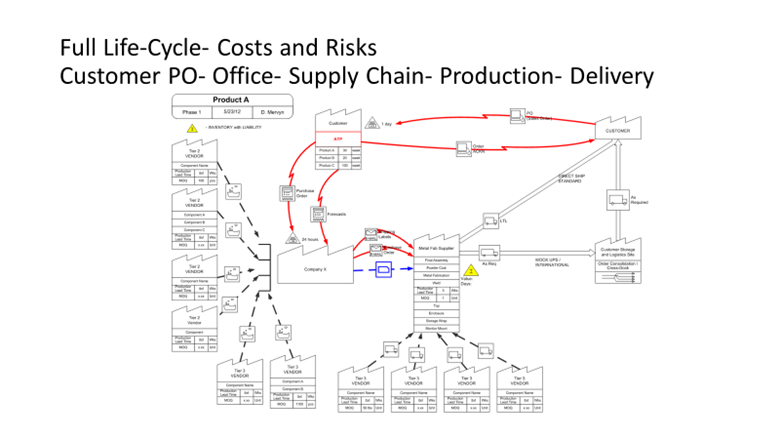

By mapping the process (Value Stream) and going to GEMBA, problems/ issues and solutions/ improvements, and cost of goods sold (COGs) and margins could be assessed. (GEMBA is a Japanese term for going to the real place and observing what is really happening.)

Accurate cost accounting exposes hidden costs chipping away at margins. Some costs are typically assigned to overhead and administration, when they should be attributed to COGs.. Some of these costs are associated with issues or problems or unactualized improvement opportunities. Using Value Stream mapping these costs (labor, direct and indirect costs) can be extracted from overhead and admin. In some cases, the outcome is a surprise. In others it quantifies the cost accurately. In both cases, better informed decisions and improvements can be made by the leadership team, owners, board members, and accountants.

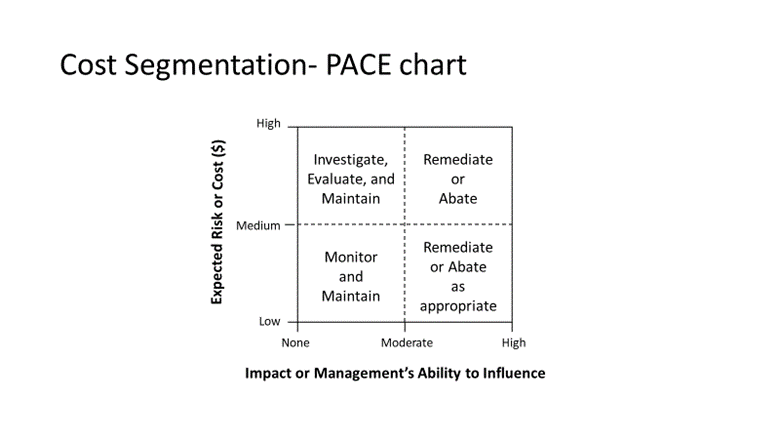

Based on cost and impact, issues and solutions and opportunities for improvement can be ranked using a cost segmentation chart.

Case Study 1- Design Engineering and Manufacturing Firm

For one client, we evaluated three product families and discovered margins were eroded from 50% to 30% and 30% to 20% (break even, no profit) for two product families. For a third product the margin was below breakeven. More importantly solutions were clear.

Solution

- Hold the Chinese supplier responsible for quality. Parts were returned at their expense for rework or the parts were scrapped or reworked in the U.S. at their expense. This change resulting in $1 million savings the first year.

- Partner with this supplier to help them improve process controls and their quality system. Once the partnering process was initiated the supplier performance improved significantly.

In addition, this assessment laid the groundwork for a series of improvements including changes in procurement planning and tactics, customer complaint management, and product launch (New Product Development) planning.

Case Study 2- Food Industry

For this client, we evaluated two production lines including mixing, sheeting, baking and packaging. We completed a production process Value Stream assessment to addressed production capacity, speed and scrap. Lack of standard processes and training; and equipment and controls malfunction were common. High levels of production inefficiency and scrap resulted. Equipment repair and maintenance were also an issue.

The Mervyn Group worked with an in-house cross-functional team to implement improvements identified in the Value Stream assessment. Together we improved efficiency of production and maintenance resources and equipment, decreased production and equipment breakdowns, malfunctions and shutdowns, scrap, and improved management and employee morale and retention.

Other Case Studies

Mike Schindele, Axiom Electronics in Hillsboro, Oregon, has used Value Stream costing to evaluate Electronic Manufacturing Service suppliers in China and Mexico and near shore manufacturing to alternative suppliers in an alternative SE Asian country and the U.S. respectively. Quality and delivery improved 80% to 95% while risk was significantly reduced through the proper vetting, review, and selection of the perspective suppliers.

In 2012 I was invited to speak on this topic and technique that “I had developed”. A business associate called and let me know the WSJ had just released article on this same topic.

This method was being used to Reshore products and improve quality and delivery, at same or lower costs than China manufacturers for Whirpool, CharBroil, Masterlock, and more.

Later I discovered that my “invention” had a name “Value Stream Cost Accounting” or “Lean Accounting”. It was not my invention. More organizations are using this powerful tool. LINK.

Hand in hand with cost accounting the companies are driven to make improvements in operational efficiency using Operational Excellence, Lean manufacturing, Sales Inventory and Operational Planning. Key to be able to compete with offshore sources is the need to improve Operations and Production efficiency in order to lower costs and meet quality and delivery targets. A combination of improvements enable companies to reduce costs of goods, stay competitive and exceed China factory performance.

To learn more about

- Value Stream Mapping and Costing,

- Industrial and process engineering (Operational Excellence and Lean) and

- Sales Inventory and Operational Planning

Contact Debra Mervyn (Debra@MervynGroup.com).