Post Pandemic Procurement Article 2: Supplier Qualification and Partnering

Presentation- Idaho Manufacturing Alliance- March 2023

Debra Mervyn/ Mervyn Group and Mike Schindele/ Axiom Electronics

Introduction

This Article (2) is the second in a series (See Article 1 Risk Management) describing the material I presented at the Idaho Manufacturing Alliance Supply Chain Business Opportunities Conference March 14, 2023, Boise. Mike Schindele, Director Supply Chain Axiom Electronics was a source for the presentation and is co-author for Article 2.

Bottom line, all industry sectors are impacted by Covid and post supply chain ramifications. Solutions are clear. One of the solutions to these challenges is best practices of Supplier Qualification, Management and Partnering.

Supplier Qualification, Management and Partnering- Best Practices

Supplier qualification and performance monitoring systems have been around a long time. The systems and processes are effective and work if implemented fairly, openly, and honestly. What could go wrong without these processes?

- A Production Manager did not evaluate the new sub assembly supplier because he knew and liked the owner whom he had met at a networking event.

- The new owner purchased a company with legacy suppliers who had never been qualified or requirements given to them for quality and delivery. Parts and materials were always delivered late and with defects.

- The Supplier was purchased and moved their manufacturing location but did not inform their Customers. Quality became an issue that caused a product recall / return of a medical device.

- Purchase orders do not have requirements and Ts and Cs. Poor quality products are delivered that require major rework by the company.

Steps – Simple and proven

- Establish Tiers based on Supplier priority or criticality

- Conduct risk assessment- Hazards Analysis (See Article 1)

- Qualify Suppliers and create Approved Supplier List and contract requirements

- Create Standard Work Instructions for Supplier qualification and purchasing

- Track Performance – quality, delivery, Customer service metrics

- Partner with critical Suppliers

Step 1- Establish Tiers

Establish Tiers based on product or service the Supplier provides and level of risk and scrutiny needed to manage the organization. (See PowerPoint presentation- Slide 12.)

Step 2- Risk Assessment

Complete a risk assessment of Suppliers. (See Article 1).

Step 3- Qualify Suppliers, Create an Approved Supplier List and Contract Requirements

Qualify Suppliers by asking them to complete a Self-Survey or Assessment. Qualify the supplier based on specific criteria and complete a record of the qualification. (Slide 16 and 17). Have the appropriate and cross functional managers approve the Supplier. The qualification approval may include the President/ CEO and Vice President or upper management depending on product or risk. Other approvers could include the Production Manager and Quality Manager, for example. In some cases a supplier assessment may be appropriate.

Create and document your Approved Supplier List. Create and document requirements for Suppliers. Axiom developed a one-page document which describes requirements for each type of Supplier. This document ensures requirements are clearly communicated within the organization. (Slide 13)

Create purchase orders (POs) with specific requirements and support the PO with a contract and or terms and conditions. Long term Supplier agreements are more important than ever given the global supply chain and logistics challenges. Still companies issue POs without specific requirements and wonder why the Supplier’s finished good is delivered late and with poor quality. Now is the time to reset expectations with Suppliers. If the ERP system is capable, create limitations for issuing a purchase order for an unapproved Supplier.

These processes are part of the organizations best practices and included in Standard Work.

Step 4- Standard Work- Processes and Procedures

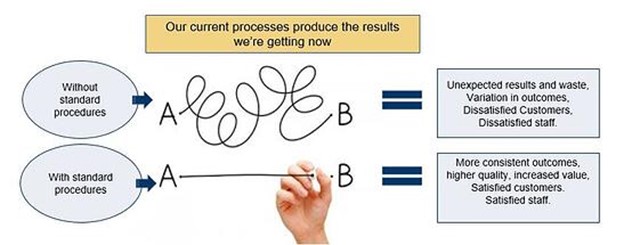

Standard processes yield consistent results.

(The Karen Martin Academy Graphic)

To achieve consistent results, standard processes must be documented in a procedure and training provide to employees. How simple, but avoided in many organizations, with devastating outcomes including financial losses or company acquisitions. Documented Standard Processes or Standard Work has the following benefits.

- Benefits

- Improves

- Quality

- Decision making

- Reduces

- Risk

- Costs

- Errors and rework

- Variation/ increase predictability

- Creates organizational flexibility

- Ability to respond to Customer needs and changing markets

- Facilitates training, cross training and work share- retention

- Creates baseline for improvement

- Increased happiness- (Yes because people are not running aground with each other as much!)

- Improves

Step 5- Supplier Performance

Supplier performance metrics typically include Quality and On-Time-Delivery. Often Customer Service is monitored but this metric tends to be squishy and subject to opinion. Post Covid, separating quality and delivery performance may be good idea since Suppliers have less and less control over lead times and On Time Delivery.

In the past an annual supplier performance reviews may have been adequate. Post Covid, quarterly is best practice since lead times and quality are changing continually. (Slide 19)

Feedback to the supplier or letter of performance to Tier 1 and critical Tier 2s is mutually beneficial. Letting the Supplier know their performance is monitored creates a feedback loop. Letting them know how much they are valued encourages them to sustain performance and improve, as needed. Peter Drucker- What gets measured, gets managed.

Axiom revitalized a program where they track the monthly OTDIF (On-Time Delivery in Full – e.g. if less than 100% of a quantity ordered is delivered = 0 points for OTD), and quality for approximately 50 suppliers. These monthly scorecards are rolled up into a master scorecard organized by Commodity/Supplier Type (e.g. Distributors, Custom Cables, PCB’s, Custom Fabricators, etc.) and compared within their commodity group. The overall results are also reviewed quarterly in their quality management review meeting, as part of Supplier performance and supply chain risk.

Step 6- Business Reviews and Partnering

Many larger companies implement quarterly business reviews with their critical suppliers (Tier 1 and critical Tier 2).

Axiom extracts performance data that is used in business reviews with both Tier 1 and 2 suppliers (approximately 15 companies). Additional items on the business review agenda include:

- Business outlook (from both parties) – How business is going, growth plans, market conditions.

- Spend history – Including a comparison of Axiom data with the Supplier’s.

- OTDIF performance.

- Quality performance – Including any SCAR (Supplier Corrective Action), and Technical Advisory issues regarding quality, when Axiom repaired internally.

- Overall performance – Including Customer service (e.g. response time, accuracy of data, flexibility.

- Upcoming deliveries or forecasts for any issues such as shortages, changes in lead time, capacity challenges, etc.

- Opportunities for improvement – Including future changes, enhancements in communication methods, etc.

Partnering

(Slide 20)

Quarterly business reviews are foundational for Supplier (or Customer) Partnering.

The Mervyn Group has successfully developed Supplier (and Customer) Partnering relationships for our clients. An example of one of these programs is a client’s Partnering relationship with Tier 1 Sheet Metal Fabrication Suppliers in Oregon.

The program is founded on quarterly on-site business, operations and manufacturing reviews with my client and the Supplier’s top management. Like Axiom’s quartering business reviews, this meeting has an agenda (Similar to Axiom’s with the addition of Work Force Issues. See below.) and is an open discussion on topics and solutions. During the meetings, the Customer and Supplier jointly make plans to address issues and improvements. Minutes of the meeting are created including action items. Action items focus on correcting and preventing issues associated with procurement, operations, manufacturing, and delivery. Action items are jointly led and completed by both my client and the supplier working together.

Development of launch plans, assembly instructions, packaging instructions, and other manufacturing protocols are led by my client or the Supplier with support from the other, working as a team. My client staff is on site at the Supplier to monitor production batch builds and assist, as needed. The team works hand in hand to fill gaps in technical documents, staffing, communication, and training.

Due to Work Force challenge, pre during and post Covid, more Customer and Supplier Partnering and resource sharing are needed to address human resource issue.

Example Agenda

Company and Supplier Plans, Wins and Challenges

Supplier

- Work Force- Resources and Staffing

- Quoting

- Pricing

- Line set up and launch

- Suggestions for improvement

Company

- Business climate and orders

- Existing and future orders and scheduling, launch plans

- Work Force- Resources and Staffing

- Requests for quote

- Cost and cost management

- Quality and OTD, root cause and corrective and preventive actions

- Suggestions for improvement

Contact Debra Mervyn Debra@MervynGroup.com to learn more.

Next Article- Additional solutions for global procurement challenges including Value Stream Mapping and Costing, Customer Partnering and Work Force Root Cause and Solutions.